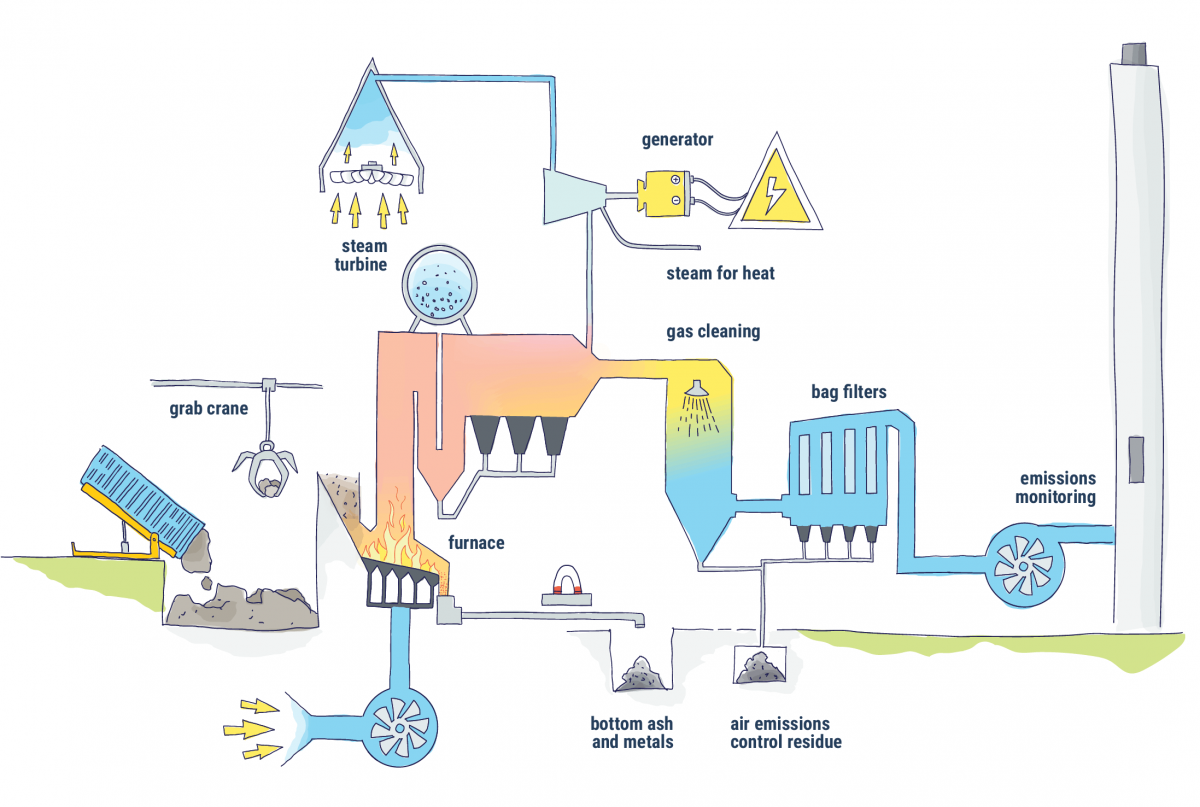

Waste is delivered to the Wilton energy-from-waste facility by train. It is tipped into the bunker, where it is mixed to ensure an even burn.

The waste is loaded by crane into the hopper, then travels down the feed chute into the furnace.

Inside the furnace, a series of grate bars move the waste through the furnace where it is dried and burned at temperatures of around 1,000°C.

Burning waste in the furnace creates hot flue gas, which is used to heat water in the boiler pipes.

The hot water is turned into steam, which drives a turbine to generate electricity for the national grid and heat for local industry.

The bottom ash, left after burning the waste, is processed on site – the metals are extracted for recycling and the remaining ash is treated before being sold as an aggregate.

The air emissions control system chemically cleans the flue gases to remove pollutants and passes them through bag filters to capture solid particles. The

resultant air pollution control residue is sent for treatment and specialist disposal.

The cleaned gases are released through the stack. Emissions are continuously monitored and are regulated by the Environment Agency.